DEPARTMENT OF MECHANICAL ENGINEERING

ABOUT MECHANICAL DEPARTMENT

The Department of Mechanical Engineering was established in the year 2012. The course offers a deep insight into the discipline and enables promising engineers to acquire skills required to succeed both individually as well as in Industry. Keeping in view of the technological advancement, the department is fortified by the most qualified and experienced faculty. The department is well equipped with modern laboratories. The Department offers 4 years B.Tech programme with intake of 120 seats.

VISION & MISSION OF THE DEPARTMENT

Vision

Through the excellence of its people, the Department of Mechanical Engineering will be recognized as a leader of its discipline in a manner that exemplifies the learning, discovery and engagement.

M2: To share knowledge through educational programs and the dissemination of our new discoveries.

M3: : To create knowledge through research in the science and technology of mechanical engineering.

Dr. D. Sudhakara Ph.D

A very warm welcome to the website of the Department of Mechanical Engineering, SISTK. The discipline of Mechanical Engineering has a long and distinguished history of developing state-of-the-art technologies and exhilarating solutions for the mankind. Ever since the establishment of this institution, our primary goal for undergraduate students is to train future leaders with high-quality engineering education. Our dedicated faculty tries to disseminate amongst the students the latest developments in Applied Mechanics & Design, Dynamics & Control, Thermo-fluids & Processes, Energy, Materials & Manufacturing, and Automation & Robotics

In today’s fast-changing world, the ever-growing challenges of limited resources, rapid climate changes and preservation of environment demand a new generation of Mechanical Engineers cultivated in the necessary skills and innovative spirit to meet them. Through a nice blend of course work and projects, the Department endows students with the ability to apply knowledge of science, mathematics and engineering to work effectively in multidisciplinary teams, provide leadership and technical expertise, and practice engineering with ethical approaches and concern for society and environment. The attempt is to provide our students with a cheerful, productive and satisfying experience at all levels of their programme of studies to explore the amazing world of Mechanical Engineering.

The pages within our website will help you explore the exciting avenues that a Mechanical Engineering course and career has to offer. You will find that the Department is very actively pursuing research in diverse fields ranging from composites, bio-heat transfer, renewable energy, cryogenics, material processing, MEMS and others. Perhaps the pages will also find the interest of a visitor from industry or academia to forge a fruitful collaboration with us in the relevant area of research or expertise.

DEPARTMENT MOU'S

The institution has very good interaction with the various industries.

The various innovative centers are established like Microsoft innovation Centre, IBM Centre of Excellence, APITA, Start-up Incubation Center, and Skill Development Center etc.

i) Central Institute of Tool Design (CITD):

Our institution signed a MOU with CITD, Hyderabad on 9th October 2014.

CITD is established in 1968 by the Govt. of India with the assistance of UNDP and ILO, is a pioneering Institution in the field of Tool engineering in the Country.

The Institute was initially established as a United Nations Development Program (UNDP) Project and was executed by International Labour Organization (ILO).

The Precision machinery and equipment was donated by UNDP and the faculties were trained abroad in the area of Tool Engineering. The UNDP Experts stayed at CITD for about 5 years and trained officers, faculty & staff of CITD in manufacture and design of tooling.

The main objectives for this institute are:

Training of the technical personnel in Designing & Manufacture of Tools, Dies & Moulds.

Design & Manufacture of dies, jigs, fixtures and gauges, etc. Provision of advisory services to Small Scale Units including assistance in design and developing tools for various processes.

In the part of MOU, the CITD offering summer internship and training programs to the interested students at its office - project locations to get hands on experience of live projects.

Depending on requirements, CITD offering specific projects with identified deliverables to be executed.

i) Unitechtransfer GmbH – German Centre for Automation and Robotics:

For students’ career, development the institution undersigned a MOU with Unitechtransfer GmbH – German Centre for Automation and Robotics.

Company responsible for following activities in organisation of Internship-Project and Placement execution and all related matters.

The main activity includes remote theoretical and practical training from German and remote student assistance.

Designing the tasks according to the current Industry needs for Indian students which can be executable within 2-3 months according to the current Industry needs for Indian students.

Providing the technical infrastructure at the institute: Software to operate from India.

German experts to support the Indian universities during the complete period of task execution.

ii) HSS BIM Solutions Private Limited:

For students’ career development the institution undersigned an MOU with HSS BIM solution private limited.

The objective of the MOU is to train the student on AutodeskTM certification programs (AutoCAD, Autodesk@ Simulation CFD Motion, etc.) to meet the industrial needs for the career development of the students.

They are providing latest software version of Autodesk Education Master Suite – 125 licenses at fee of cost

Through its education community portal address technology access is provided for faculties and students with free student demo version license.

iii) Start-up Incubation centre:

The Start-up Incubation Centre to our institution has been sanctioned by the A.P. State Government, as a part of Sunrise Start-up programs for students on Jan 2015.

A.P. State government has sanctioned total 38 incubation centres in state (5 for Chittoor district) through this. Among those one is our institution.

It is a privilege to our institution to run incubation functionality for the development of student Entrepreneurs.

Student committee has been formed and approved by start-up village, Visakhapatnam. This committee is working on incubator functionalities under the guidance of Coordinator and Head of the Institution.

iv) Start-up Incubation centre:

Department of Science and Technology (DST) New Delhi has sanctioned total 2 incubation centres at Chittoor district in the academic year 2016-2017. One is our Siddhartha Institute Puttur got sanctioned Rs.7 Corers and another one Padmavathi Mahila University,Tirupati got sanctioned Rs.2 Corers.

Incubation cells are formed (Idea Park, Innovation cell, Techno park cell, Innovation Management cell)

It is a privilege to our institution incubation centre got MOU with total 19 industry academic partnership

Industry academic partnership program inaugurated for getting more MOU with industries

v) Skill Development Centre:

Aiming to promote innovation among students, the Andhra Pradesh government launched 17 skill development centres across the state where students from colleges and universities would take part in developing mobile apps and other skills.

It is proud that among those one is our institution throughout the state.

It is started with a batch of 30 students in Phase – I.

They developed 10 Android Apps in the duration of 2 weeks (05-01-16 to 17-01-16).

Two students of phase – I was awarded two android mobiles by our honourable Chief Minister for their apps development.

Phase – II started in the same year with 50 students, divided into 10 batches with 90 numbers of sessions.

vi) IEG Andhra Pradesh Information Technology Academy (IEG APTIA):

Student training activities will be done in the name of “Amaravati Knowledge Center”.

The Main Objectives of APITA are

Support capacity building initiatives of Information Technology, Electronics and Communications Department of Government of Andhra Pradesh.

Develop and offer courses in IT, Electronics and Communications in collaboration with Industry and Academia.

Bridge the urban rural divide in producing readily employable graduates.

Provide conductive environment for learning through value addition programs.

Promote a culture of Research and Development in IT, Electronics and Communications.

Facilitate e-governance through oriented programs for state government employees.

Offer consultancy support in Capacity Building Programs.

Collaborate with Industry, Educational and Research Institutions for the promotion and development of e-Governance.

National Instruments (NI) Competence Development Program

NI will provide training to faculties on LabVIEW software platform & Measurement and Automation hardware platform free of cost.

IEG is authorized training and certification center to conduct LabVIEW skill development courses at campus for students and faculties.

After the successful completion of the course, IEG & NI can jointly issue participation certificate with NI logo to the participants.

After the Successful completion of the course, the students can appear for globally recognized certification exam Certified LabVIEW Associate Developer (CLAD) and passing the exam will enable the students to get job-entry in core engineering industries.

Huge discount on CLAD exam fees ie. Rs. 3000 + Tax (Original Price is Rs. 9000) as applicable to every IEG membership student & faculty.

The NI CLAD certified students can do their final year projects - internships at NI industry customers in India.

Students can do experiments beyond the curriculum.

Students can do in-house final - pre-final year real time projects.

Students will get opportunity to get in to core engineering industries.

Students can participate in National and International Conferences.

Students can publish in National & International journals.

Career development and job opportunity through NI community.

Certification Program in Animation:

Animation work mainly involves the concepts of modeling, texturing, rigging, facials, fur and hair, layout, animation, lighting, compositing, and visual effects, and to learn the technology in-depth it needs minimum of 6 months.

DQ Entertainment is developing a course that suits to the JKC students with duration of 3 or 4 days (50% theory and 50% practice) with extended hours of training.

The course will be designed to provide the basic knowledge of animation, how it works and ignites the student thinking.

The material and software required for training, learning and practicing will be supplied by DQ team free of cost.

Based on the inputs and interests from the colleges Level I, Level II, and Level III certification courses will also be developed.

Certification cost is Rs. 1300.

Autodesk Education program

IEG is the Autodesk Authorized Training Center and is also considered as Autodesk Academic Partner in Andhra Pradesh.

Autodesk has introduced training and certification program on Autodesk products in Engineering Colleges associated with APTIA

Mechanical, Civil, EEE and ECE students are eligible for joining this program.

Faculty Development Programs will be conducted.

Student Competitions, Boot Camps, and workshops will be conducted.

Certification fee is Rs. 1100.

Soft skills Program

IEG is offering Two Day Activity Based Soft Skills Workshops free of cost.

Experienced - senior Soft skills specialist will train the students at the college.

Training is focused on Employable Skills: Communication Skills, Presentation Skills, Interview Skills, Group Discussion Skills, Attitudes and Behavior, Corporate Etiquette, Case studies etc.

JAM sessions and individual mock interviews will be conducted so that the students can perform better in the recruitment drives.

Aptitude and Reasoning

IEG is offering training in Aptitude and Reasoning for the students.

Training would help students in cracking the competitive exams and Job opportunities.

vii) Microsoft Innovation Centre:

Our institution is one among 45 institutions in India to have Microsoft Advantage Platinum level status and also the Microsoft Innovation Centre (MIC).

This initiative has helped more than 500 students to get certified on Microsoft technologies.

Many students are honing their skills on Microsoft technologies in MIC.

Students are even developing projects and apps for mobile devices in MIC.

This initiative has created a vast awareness of latest technologies among the students and the staff.

The institution has – Microsoft Innovation Centre established within the campus to foster critical thinking and innovation among the students.

Students are encouraged to work on Microsoft technologies and create new products and services using the same.

Hackathon program conducted on 31st Jan 2015 by the institution and more than 500 apps are uploaded in online.

MIC is trains our students as per requirements of MNCs.

Interaction with industry:

1. The college has entered into MOUs with leading industries, which are being pursued actively.

2. An active Entrepreneurship Development Cell is headed by a senior Professor to mould the students to become Entrepreneurs.

REGULATIONS & SYLLABUS

MECHANICAL DEPARTMENT LABORATORIES

Engineering Workshop lab:

Equipped with carpentry section (including all Tools), Fitting Section (including all Tools), Sheet metal section (including all Tools), Electrical Wiring section (including all Tools), Welding section (including all Tools), Foundry section (including all Tools), Black smithy (including all Tools).

Mechanics of Solids Lab:

Equipped with Direct Tension Test Beam (UTM), Torsion test capacity – 10 Kg, Rockwell Hardness Tester, Brinnel Hardness Tester, Test on springs, Izod Impact test, Punch shear test, Steel Beam for flexure test, Continuous beam Setup and Beam set up for Maxwell’s Theorem verification.

Material Science Lab:

Equipped with Metallurgical Micro scopes, Hydraulic Specimen Mounting Press with Accessories, Belt Grinder, Muffle Furnace With Digital Indicator, Standard Metallographic Samples, Jominy and Quench Apparatus (stain less steel model) and Tilting Crucible Furnace

Fluid Mechanics and Hydraulic Machinery Lab:

Equipped with Impact of Jets on vanes, Performance Test on Pelton Wheel, performance Test on Kaplan Turbine, Performance Test on Single Stage Centrifugal Pump, performance Test on Multi Stage Centrifugal Pump, estimation of loss of head due to sudden contraction in a pipeline, Bernoulli’s Theorem, Turbine Flow meter and Hydraulic Jump.

Thermal Engineering Lab:

Equipped with Cut section model for Value timing study using 4 stroke single cylinder, water cooled diesel engine- mounted on table with marking of Angle scale on the fly wheel, Cut section model for Port timing study using 4 stroke single cylinder, water cooled Petrol engine- mounted on table with marking of Angle scale on the fly wheel, Babcock and Wilcox Boiler, Locomotive Boiler, Cochran Boiler, Lamount Boiler, Benson Boiler and Loeffler Boiler.

Manufacturing Technology Lab:

Equipped with Plastic Injection Molding Die (Bottle Cap), Plastic Blow Molding Die: (1/2L BOTTLE), Hydraulic Press SIZE 50 Tons, FLY PRESS”8’’n a. Die (Blanking) b. Die (Piercing) c. Die (Bending) d. Die (Deep Drawing), Spot Welding Machines 10 KVA, TIG Welding Set AC/DC, Arc Welding, Permeability Tester, Tilting Crucible Furnace Capacity (5kg) Aluminum With Digital Indicator and Sand Rammer

Metrology and Measurements Lab:

Equipped with Digit Vernier Caliper (0-150 mm LC 0.02 mm 500-196-20), Digit outside Micrometer (0-25 mm LC 0.01 mm 293-240), Inside Micrometer (5-30 mm 145-185), Vernier Height gauge (0-300 mm 514-102/103), Tool Makers Microscope 30X:75X:,150X, Bevel Protractor “ OCEAN” make, Sine Bar-200mm INDIAN Make, Slip Gauge set M87 OCEAN Make, Floating carriage Micrometer (college model) EDMM-100/CL, Mitutoyo “surf Test” Model no.SJ 210 and Surface Plate 630X630 mm MS Fabricated stand with Leveling Screws for 630 x 630 mm

Heat Transfer Lab:

Equipped with Thermal Conductivity Of Metal Rod, Thermal Conductivity Of Insulating Material, Heat Transfer Through Composite Wall, Heat Transfer In Pin / Fin, Heat Transfer In Forced Convection, Heat Transfer In Free / Natural Convection, Parallel And Counter Flow Heat Exchanger, “Stefan Boltzmann’s Constant” Apparatus, Condensation Phenomenon Apparatus (Drop And Film-Wise Condensation) and Emissivity Measurement Apparatus

DEPARTMENT NEWS

EVENTS FOR ACADEMIC YEARAPR-JUNE 2016

JAN- MAR 2014

JAN-JUNE 2013

Jan-June

JULY -SEP 2016

JULY-SEP 2014

News letter oct-dec 2016

OCT-DEC 2013

OCT-DEC 2016

Board of Studies Members (MECH)

CONSOLIDATED DATA

| S.No. | ACADEMIC YEAR | NAME OF JOURNALS |

|---|---|---|

| 1 | 2017 - 2018 | 5 |

| 2 | 2016 - 2017 | 3 |

| 3 | 2015 - 2016 | 3 |

| 4 | 2014 - 2015 | 3 |

Research Publication for Academic Year - 2017-2018

| S.No. | Author | Title | NAME OF JOURNAL | VOLUME & PP |

|---|---|---|---|---|

| 1. | S.Suresh | Processing and mechanical tastings of 7075 al matrix composite reinforced with AL2O3 Nano-particles fabricated by stir casting route | IJMPERD | Volume 8- Year 2018 |

| 2. | S.Suresh | Mechanical Behavior Of Al 7075 Reinforced With Al2O3 And SIC Nano Particles Fabricated By Stir Casting Method | IJMPERD | Volume 8-Year 2018 |

| 3. | Dr.Dara Sudhakara | Optimization of parameters in wire-EDM for powder metallurgical cold worked tool steel | IJRSET | Volume 4-Year 2018 |

| 4. | R.Sandeep | Experimental study of double sided friction stir welding of AA 6061 plates using hexagonal tool tip | IJRAT | Volume6-year 2018 |

| 5. | R.Sandeep | Experimental Study And Optimization of Double Sided Friction Stir Welding of AA 6061 Plates | IJAERD | Volume5-year 2018 |

Research Publication for Academic Year- 2016-2017

| S.No. | Author | Title | NAME OF JOURNAL | VOLUME & PP |

|---|---|---|---|---|

| 1. | S.Suresh | Processing and mechanical tastings of 7075 al matrix composite reinforced with AL2O3 Nano-particles fabricated by stir casting route | IJMPERD | Volume 8- Year 2018 |

| 2. | S.Suresh | Mechanical Behavior Of Al 7075 Reinforced With Al2O3 And SIC Nano Particles Fabricated By Stir Casting Method | IJMPERD | Volume 8-Year 2018 |

| 3. | Dr.Dara Sudhakara | Optimization of parameters in wire-EDM for powder metallurgical cold worked tool steel | IJRSET | Volume 4-Year 2018 |

| 4. | R.Sandeep | Experimental study of double sided friction stir welding of AA 6061 plates using hexagonal tool tip | IJRAT | Volume6-year 2018 |

| 5. | R.Sandeep | Experimental Study And Optimization of Double Sided Friction Stir Welding of AA 6061 Plates | IJAERD | Volume5-year 2018 |

Research Publication for Academic Year- 2015-2016

| S.No. | Author | Title | NAME OF JOURNAL | VOLUME & PP |

|---|---|---|---|---|

| 1. | R.Sandeep | Multi objective optimization of process parameters in plasma arc cutting of SS 420 using grey-taguchi analysis | IJAERS | Volume2-year 2015 |

| 2. | P.Rajesh | Experimental and parametric studies of Nd:YAG laser drilling on austenitic stainless steel | Springer | Volume-year 2015 |

| 3. | p.Rajesh | Experimental studies on austenitic stainless steel using Co2 laser cutting machine | Elixir | Volume-year 2015 |

Research Publication for Academic Year- 2014-2015

| S.No. | Author | Title | NAME OF JOURNAL | VOLUME & PP |

|---|---|---|---|---|

| 1. | Dr.Dara Sudhakara | Experimental investigation of optimization process parameters of wire cut EDM by taguchi method | ICMMM | Volume Year 2014 |

| 2. | Dr.Dara Sudhakara | Application of taguchi method for determining optimum surface roughness in wire electric discharge machining of P/M cold worked tool steel (Vanadis-4E) | ELSEVIER | Volume-year2014 |

| 3. | Dr.Dara Sudhakara | Review of research trends :process parametric optimization of wire Electrical Discharge Machining (WEDM) | IJCET | Volume-year 2014 |

MECH FACULTY LIST

| S.No | Name | Qualification | Designation | Date Of Joining | Specialization |

|---|

IN PROGRESS

Faculty Acheivements

Dr. Dara Sudhakara awarded by the title of Innovative Technologist & Dedicated Teaching Professional Award from Innovative Scientific Research Professional Malaysia (ISRPM) at 2017.

Mr. P. Rajesh awarded by District Best NSS Program Officer from National Service Scheme Cell, JNT University Anantapur.

Mr. V.S. Ravi awarded by outstanding performance in teaching of the Engineering Drawing for Mechanical Engineering subject for II year – I SEM 2017 university results.

Faculty Awarded Ph.D. Degrees during the last five years while in service

Mr. Dara Sudhakara awarded Ph.D. Degree during the year 2017 by JNTU Anantapur..

| S.No. | Name of Faculty | Designation | Status | Name of the University | Year of Award / Thesis Submission |

|---|---|---|---|---|---|

| 1. | Dr. Sudhakara | Professor | Completed | JNTUA | 2017 |

The following faculty got 100% Result in University examinations

| S.No. | Name of Faculty | Academic Year | Subject Name |

|---|---|---|---|

| 1. | Mr. V.S. Ravi | 2017-18 | EDME |

| 2. | S. Suresh | 2017-18 | DOM |

| 3. | S. Bala Anki Reddy | 2017-18 | TE-I |

| 4. | V Sivakoti Reddy | 2017-18 | MT |

| 5. | D. Sudhakara | 2017-18 | POM |

Achievements of Teachers 2017-18

1.Dr. Dara Sudhakara awarded by outstanding performance in teaching of the Modern Machining Methods subject for final year – I sem 2016 university results.

Mr. R. Suresh

A Text book of “Design of Machine Elements - II” is published in the year 2016 for Diploma Mechanical Engineering as per (C-14) through FALCON Publishers, Hyderabad.

A Text book of “Production Drawing” is published in the year 2016 for Diploma Mechanical Engineering as per (C-14) through FALCON Publishers, Hyderabad.

A Text book of “Measurements and Control Systems” is published in the year 2016 for Diploma Mechanical Engineering as per (C-14) through FALCON Publishers, Hyderabad.

A Text book of “Industrial Management” is published in the year 2016 for Diploma ECE as per (C-14) through FALCON Publishers, Hyderabad.

A lab manual of “Manufacturing and Fabrication Engineering Lab – I” is published in the year 2015 for Diploma Mechanical Engineering as per (C-14) through FALCON Publishers, Hyderabad.

A lab manual of “Fuels Lab Practices” is published in the year 2016 for Diploma Mechanical Engineering as per (C-14) through FALCON Publishers, Hyderabad.

A lab manual of “CAD Lab practices” is published in the year 2016 for Diploma Mechanical Engineering as per (C-14) through FALCON Publishers, Hyderabad.

A lab manual of “Basic Workshop Practices” is published in the year 2016 for Diploma Mechanical Engineering as per (C-14) through FALCON Publishers, Hyderabad.

A Text book of “Machine Drawing” is published in the year 2015 for Diploma Mechanical Engineering as per (C-14) through FALCON Publishers, Hyderabad

The following faculties are acted as Mentor for NSS

| S.No. | Name of the Faculty. | Department | Event | Position Held | Year |

|---|---|---|---|---|---|

| 1. | Mr.P.Rajesh | Assistant Professor | NSS | NSS Coordinator | 2017 |

Faculty Joined Ph.D. Degree during the last five years while in service

| S.No. | Name of Faculty | Name of the University | Year of Admission |

|---|---|---|---|

| 1. | N.Sreedhar | Veltech University | 2016 |

100 % Result achievements by Faculty

The following faculty got 100% Result in University examinations

| S.No. | Name of Faculty | Academic Year | Subject Name |

|---|---|---|---|

| 1. | S.Bala Anki Reddy | 2016-2017 | MD |

| 2. | Dr D Sudhakara | 2015-2016 | Modern Mahiching Methods |

STUDENT INNOVATIVE PROJECTS

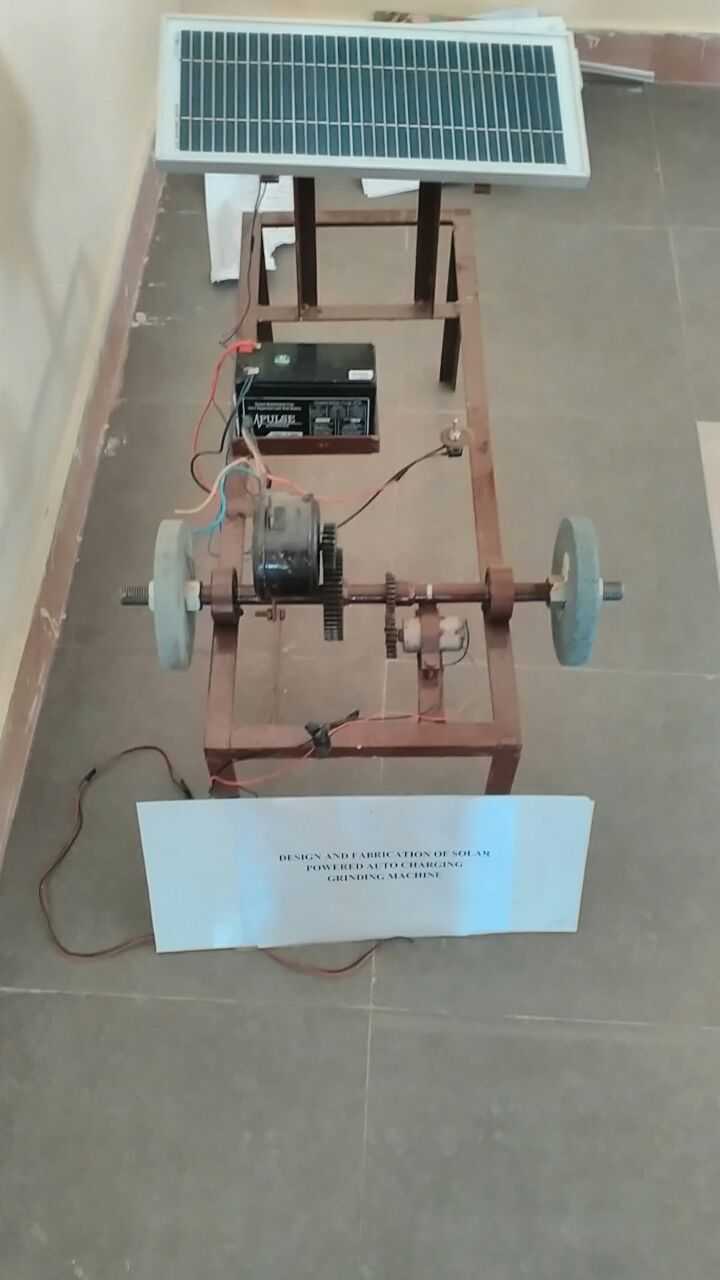

(ACADEMIC YEAR: 2015-2016)Title of the Project : DESIGN AND FABRICATION OF SOLAR POWERED AUTO CHARGING GRINDING MACHINE

Abstract: Grinding is a metal removing operation performed by means of rotating abrasive wheel that acts as a tool. This operation is used to get high surface finish and good dimensional accuracy. This project aim is to design and fabrication of solar powered grinding machine is used for grinding any shape of object like Circular, Rectangular, and Polygon. In our project grinding machine is used to grinding the different types of material. The grinding machine is rotated by the single-phase induction motor by using solar power hence our project namely solar powered auto charging grinding machine. According to the type of material to be grind, the grinding tool can be changed and speeds are varied. This machine can be widely applied in almost all type of industries. By varying the pulley sizes we can get a maximum speed up to 10,000 rpm.

Title of the Project : SOLAR OPERATED PESTICIDE SPRAYER

Abstract: As the world’s population increases and the diets of the developing world continue to improve, demand for meat and crops means food production could need to increase by up to 70% by 2050. Fertilizers will undoubtedly play a major role in this production uplift. Soil fertility largely depends on its nutrient status: the amounts and rates of nutrient supplies for plant growth. An adequate nutrient supply is an essential factor in plant growth. If there is an adequate supply of nutrients in the soil, plants are likely to grow well and produce high yields. If even one of the nutrients needed is in short supply, plant growth is limited and yields are reduced.

In Indian farms generally two types of spray pumps are used for spraying; hand operated spray pump and fuel operated spray pump. Among which hand operated spray pump is most popular. The main drawback of hand operated spray pump is that the user can’t use it for more than 5-6 hours continuously as he gets tired after some hours where as fuel operated spray pump requires fuel which is expensive and availability of fuel is not easy at rural places. At the same time it exhausts carbon dioxide as pollutant which is harmful to our environment. In such situation we should think to move towards some non-conventional energy. Considering it, solar energy would be one of the solutions. It can be most often used at various locations such as farms, gardens although it can become more popular in rural areas as well. The additional advantage of this project is it can be used as home by charging the mobile as its battery can be used at night too.

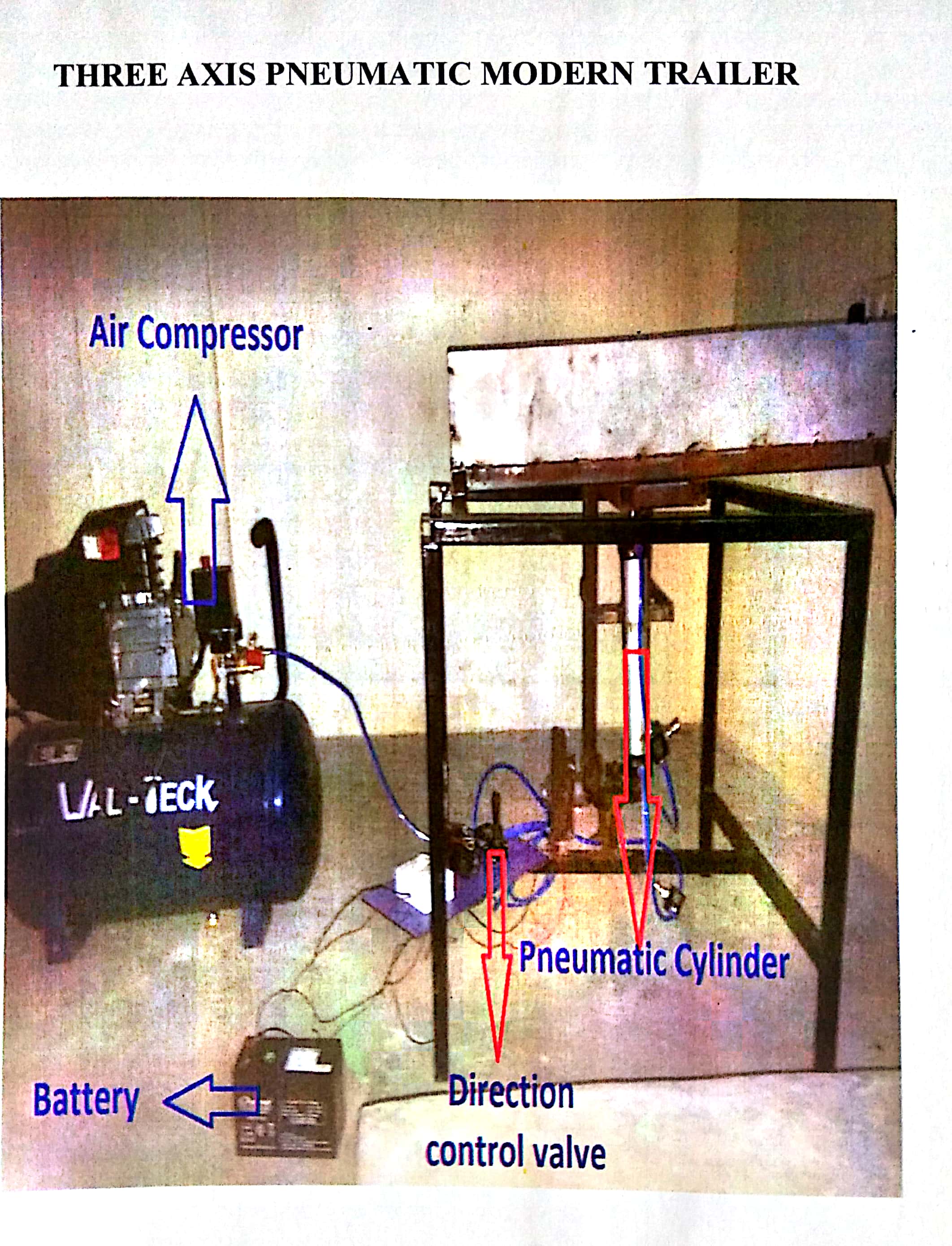

Title of the Project : THREE AXES PNEUMATIC MODERN TRAILER

Abstract: This project work titled "Three Axis Pneumatic Modem Trailer" has been conceived having studied the difficulty in unloading the materials. Our survey in the regard in several automobile garages, revealed the facts that mostly some difficult methods were adopted in unloading the materials from the trailer. The trailer will unload the material in only one single direction. It is difficult to unload the materials in small compact streets and small roads. In our project these are rectified to unload the trailer in all three sides very easily.

Now the project has mainly concentrated on this difficulty, and hence a suitable arrangement has been designed. Such that the vehicles can be unloaded from the trailer in three axes without application of any impact force. By pressing the Direction control valve activated. The compressed air goes to the pneumatic cylinder through valve. The ram of the pneumatic cylinder acts as a lifting the trailer cabin. The automobile engine drive is coupled to the compressor engine, so that it stores the compressed air when the vehicle running. This compressed air is used to activate the pneumatic cylinder, when the valve is activated.

Title of the Project : EXHAUST GAS RECIRCULATION IN SI ENGINES TWO WHEELERS

Abstract: The Aim of project is to design and fabricate an exhaust gas recirculation system in which the exhaust of an automobile is filtered and recirculates to the engine. Automobile pollution is the major source of pollution. Exhaust gas recirculation (EGR) works by recirculating a portion of an engine’s exhaust gas back to the engine cylinders. Exhaust gas is routed back into the combustion chamber because the exhausted air is much hotter than the intake air. Usually, an engine recalculates exhaust gas by piping it from the exhaust manifold to the inlet manifold. This design is called external EGR. A control valve (EGR Valve) with in the circuit regulates and times the gas flow. The exhaust gas is used to rotate the carbon filter with control by gate valve arrangement. Carbon filter used to filter the exhaust gas and pure gas to rotate to inlet manifold and unwanted gases are throughout by using gate valve arrangement. Pure gas mixture with inlet air of carburettor. It also good with regard to economic considerations and engine efficiency. In which the efficiency of the engine can be increased.

Title of the Project : VEHICLE CONTROLLING WITH ALCOHOL DETECTION

Abstract: “Prevention is better than cure", we are all well aware of this quote. Every year many lives are drunken driving. Efforts are taken to save life after the accident. These circumstances can be prevented by introducing "alcohol sensor in to an automobile. This Sensor is connected to igniting parts through the electrical circuit. On installation of the mechanism in an automobile has initially the driver has to axle on to the sensor to start up the engine.

The vehicle will start if and only if the driver passes the test condition i.e, the exhaled air alcoholic percentage must be less than the Threshold value. If the limit crosses or if the driver avoids blowing on to the device the ignition will be interlocked. The output of the alcohol sensor is directly proportional to the concentration of alcohol in the breath. Through some electronic means these output is utilized to hand over the igniting system to the breath of the driver and not his hands.

While government regulations play an important role in ensuring vehicle safety, voluntary approaches to the design and implementation of vehicle safety systems are increasing in importance as vehicle manufacturers deploy safety systems well in advance of, and even in the absence of, government regulations requiring them. This paper provides an overview of of regulatory and non-regulatory approaches to vehicle technology development and deployment, and will describe a new, innovative public\private partnership underway to develop an in-vehicle alcohol detection system. In response to concerns about limited progress in reducing alcohol-impaired driving in the United States during the last decade, attention is focusing on technological approaches to the problem.

One strategy includes efforts to increase the application of current breath alcohol ignition interlocks on the vehicles of Driving While Intoxicated (DWI) offenders. The Automotive Coalition for Traffic Safety (ACTS, a group funded by vehicle manufacturers) Highway Traffic Safety Administration (HTSA) have commenced a 5-Year cooperative agreement entitled Driver Alcohol Detection System for Safety (DADSS) to explore the feasibility of. and the public policy challenges associated with, widespread use of in-vehicle alcohol detection technology to prevent alcohol-impaired driving. This paper will outline the approach being taken, and the significant challenges to overcome.

Title of the Project : EXPERIMENTAL ANALYSIS OF VAPOUR COMPRESSION REFRIGERATION SYSTEM USING CAPILLARY TUBES AND CONDENSERS

Abstract: Most of the household refrigerator works on the vapor compression refrigeration system which has high coefficient of performance. The system consists of components like compressor, condenser, expansion valve and evaporator. The system of performance depends on the performance of all the components of the system.

The main objective of the project work is to find coefficient of performance of refrigeration system using different capillary tubes and condensers, in particular, household refrigerators and freezers. The model is based on the assumption that the length of a capillary tube is dependent on five primary variables, namely the capillary tube inner diameter, the mass flow rate of the refrigerant in the capillary tube, the pressure difference between high side and low side, the refrigerant sub cooling at capillary inlet and the relative roughness of the capillary tube material. The model is validated with previous studies over a range of operating conditions and is found to agree reasonably well with the experimental data for HFCI34a.

Title of the Project : Design and Fabrication of Manually operated Seed Planter Machine

Abstract: The basic requirements for small scale cropping machines are, they should be suitable for small farms, simple in design and technology and versatile for use in different farm operations. A manually operated template row planter was designed and developed to improve planting efficiency and reduce drudgery involved in manual planting method. Seed planting is also possible for different size of seed at variable depth and space between two seed. Also it increased seed planting, seed/fertilizer placement accuracies and it was made of durable and cheap material affordable for the small scale peasant farmers. The operating, adjusting and maintaining principles were made simple for effective handling by unskilled operators (farmers).

Keyword: Seed, Frame, Wheel, Metering Mechanism, Hopper, Seed Tube, Handle.

Title of the Project : Fabrication of Wheel Spray Pump for Agriculture

Abstract: India is a developing country. It has a rich land source which is the best suited for agriculture. Rural people, who constitute nearly 70 percent of population, are dependent on agriculture as a main occupation. It is very essential to develop methods for better agriculture. Technology can effectively alter the production rate by providing various modern agricultural implements which save man hour and money. It is also well known fact that India is characterized by low per capita income. Therefore it necessitates the technological people or the agricultural engineering who provide agricultural implements; which are most sophisticated and can be procured by the farmers at feasible rates Present day in agriculture the sprayers play an important role in spraying pesticides. Although sprayers varies like motorized, hand operated and in helicopter. The current idea on sprayer in our project is to utilize effectively, the weight of man which is wasted while moving to the field. In the conventional sprayer one has to use left hand or right hand or both the hands to give pressure. In this project an attempt is made to use the gravitational force (weight) of a person (farmer) which is wasted while walking in the field.

Title of the Project : Performance and Analysis of a Turbo Charged Two Wheeler Engine.

Abstract: In present situation everybody in this world needs to ride a high powered, high fuel efficient and less emission two wheelers. In order to meet the requirements of the people an attempt have been made this in this project to increase the power by using the exhaust gas of the engine by passing this gas on to turbine compressor arrangement, This compressor compresses the fresh air and is sent to the carburettor. The authors have mainly aimed to increase the air fuel ratio therefore all the requirements were fulfilled by this process. The result shows a reduction in fuel consumption of the base engine.

Turbochargers are used throughout the automotive industry as they can enhance the output of an internal combustion (IC) engine without the need to increase its cylinder capacity. The application of such a mechanical device enables automotive manufacturers to adopt smaller displacement engines, commonly known as "engine downsizing". Historically, turbochargers were often used to increase the potential of an already powerful IC engine.

Keywords: Turbocharger, Volumetric Efficiency, Spark Ignition Engine, Exhaust Emissions, Total Fuel Consumption (TFC)

STUDENT ACHEIVEMENTS

Consolidated Data

| S.No | Academic Year | Number of Cocurriclar activities Students |

|---|---|---|

| 1 | 2017 - 2018 | 3 |

| 2 | 2016 - 2017 | 7 |

| 3 | 2015 - 2016 | 8 |

| 4 | 2014 - 2015 | 5 |

| 5 | 2013 - 2014 | 4 |

| S.No | Year | Level | No of Students Participated | No. of Prizes Won |

|---|---|---|---|---|

| 1 | 2017 to till date | Inter-collegiate/ State/ University | 40 | 22 |

| 2 | 2016 - 2017 | Inter-collegiate/ State/ University | 36 | 20 |

| 3 | 2015 - 2016 | Inter-collegiate/ State/ University | 38 | 19 |

| 4 | 2014 - 2015 | Inter-collegiate/ State/ University | 20 | 12 |